Polypropylene hand strapping is used to secure goods to pallets so that they remain stable in transit which reduces movement and damage. It is ideals for light to medium weight products. The strapping also has elastic properties so it delivers great flexibility and durability.

It is generally used in warehouse environments and used with a hand operated tensioner and sealer. The strapping is fed underneath the pallet and over the goods. Where the two ends meet, the strapping is fed into a hand operated tensioner which when used will tighten the strapping around the palletised goods.

A metal seal is placed on the point where the strapping meets and is secured with a hand operated sealer. .

Useful Tip : If you wish to use pallet wrap aswell, do so BEFORE using the strapping. The reason being that if you strap the pallet first you will find that the pallet wrap will then bend the strapping making it less affective.

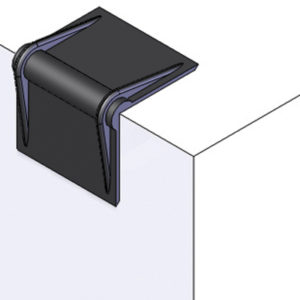

Another Useful Tip: Use scrap pieces of cardboard as edge protectors. Feed them underneath the untightened strapping to stop it cutting into the products. Well worth keeping any cardboard for this purpose.

Machine strapping has been designed to be used in a fully automatic or semi automatic strapping machine which is a much quicker process than hand strapping but you have the additional cost of a strapping machine. It is ideal for multiple small parcels that need to have the security of bands of strapping or to join parcels or products together.

Yet Another Useful Tip: Check with your courier company first before using machine strap on parcels. Some couriers do not like it as it gets stuck on their conveyor belts.