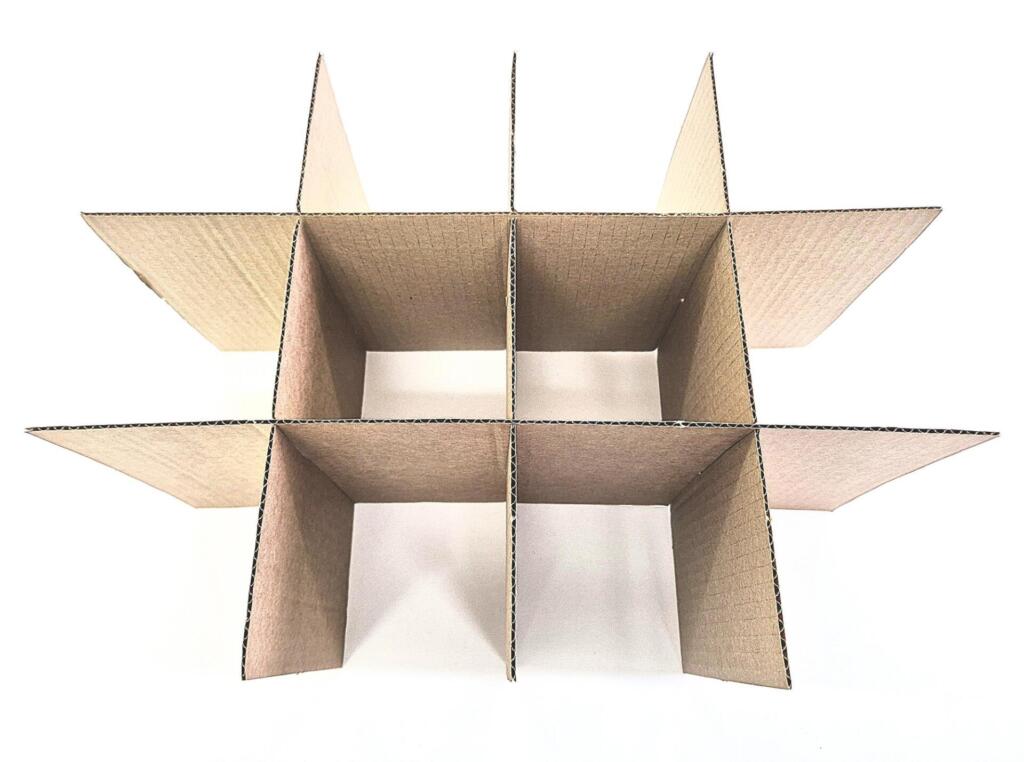

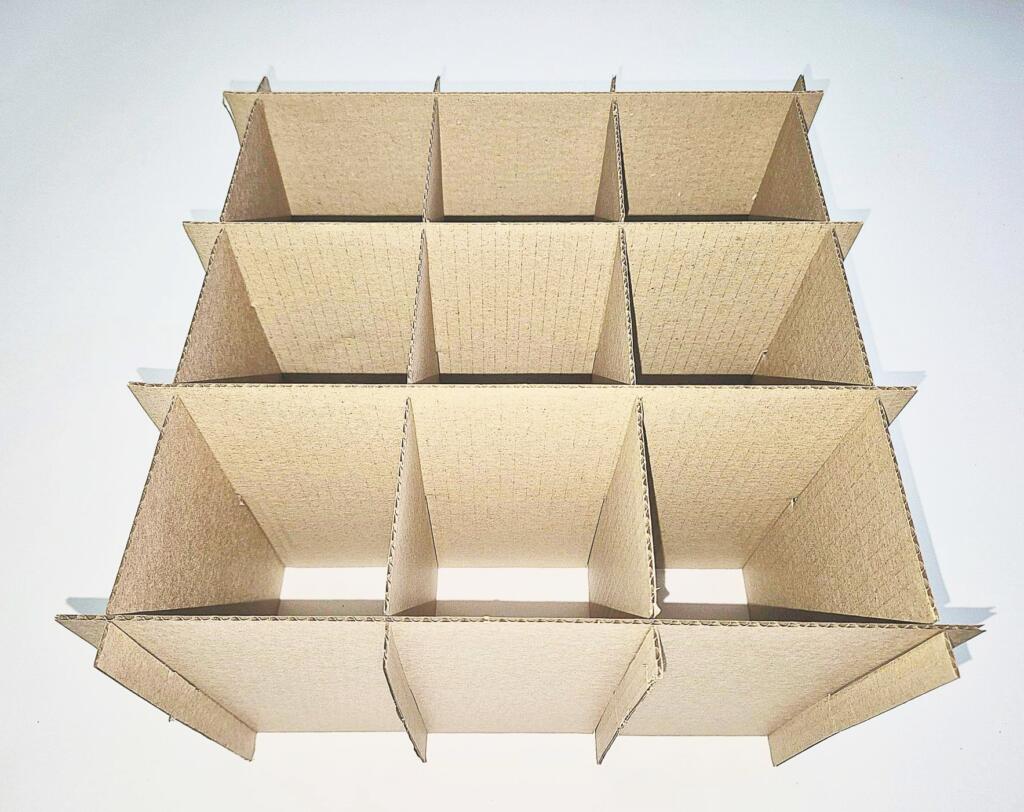

At makkipak we are increasing our range of glass bottle packaging. We have a range of packaging ideas that’s aimed at protecting small bottle used in the apothecary and medical industry. Cardboard divisions are an excellent eco friendlier way of separating bottles. Although a little time consuming to assemble they are an economical and efficient way of using the space available within the outer box. Cardboard divisions also increase customer satisfaction as the bottles are presented far better than simply wrapping in tissue paper or bubble wrap. Even though the packaging ends up in the recycling bin, it is still very important that your customer sees that effort has been made to protect their purchase through the rigors of the courier network.

At makkipak we manufacture all our bespoke divisions and outer boxes. That means you are ordering straight from the manufacture ensuring you are getting the best price. You also have access to our wealth of knowledge as many of our staff have worked within the packaging industry for 20 years.

At makkipak we have die cutting machinery and box makers that are designed to manufacture short run corrugated boxes. We have been designing and manufacturing packaging for over 25 years and while we still supply the usual stock sized cases, more and more customers now see the value in turning to bespoke as it can drastically reduce the amount of void fill, save space in an already overcrowded packing area and offers superior protection.

At makkipak we have die cutting machinery and box makers that are designed to manufacture short run corrugated boxes. We have been designing and manufacturing packaging for over 25 years and while we still supply the usual stock sized cases, more and more customers now see the value in turning to bespoke as it can drastically reduce the amount of void fill, save space in an already overcrowded packing area and offers superior protection.

Sending glass bottles through the courier network can be a tricky business. Costs can mount up with using too much void fill and unnecessarily large outer boxes. Glass bottles often break in transit because there is movement within the box or the outer box is unable to take the weight of a driver walking on it (yes, this happens alot, just look in the back of your couriers van next time it pulls up !). The outer box must be able to withstand the weight of the courier driver, that could be anything between 60 and 100 kgs ! Not only that, your parcel could be buried beneath hundreds of other parcels. If there are any weaknesses in the packaging, they will certainly be exposed when sent through the courier network. If the box is not fully packed or the outer box is not made of strong corrugated it is liable to be crushed. Corrugated divisions can prevent this from happening as a lattice spreads the weight over a larger surface area. When the divisions are made to the full depth of the box, there is no void that can be crushed. The divisions and outer box take the strain, protecting the glass bottles. Void fill such as paper, bubble wrap and tissue paper can absorb the energy from shocks but it’s not very good at protection from crushing. Next time you package your product we recommend you do a drop test by dropping the package from waist height. One more bit of advice, your parcel will not be neatly placed in the van at the depo. Couriers are under alot of pressure to dispatch as many parcels as possible !

We hope this advise has helped you with your packaging dilemmas but if you are still unsure how to package your glass bottles just give us a call on 01604 812755 and a member of our sales team will provide expert advise.